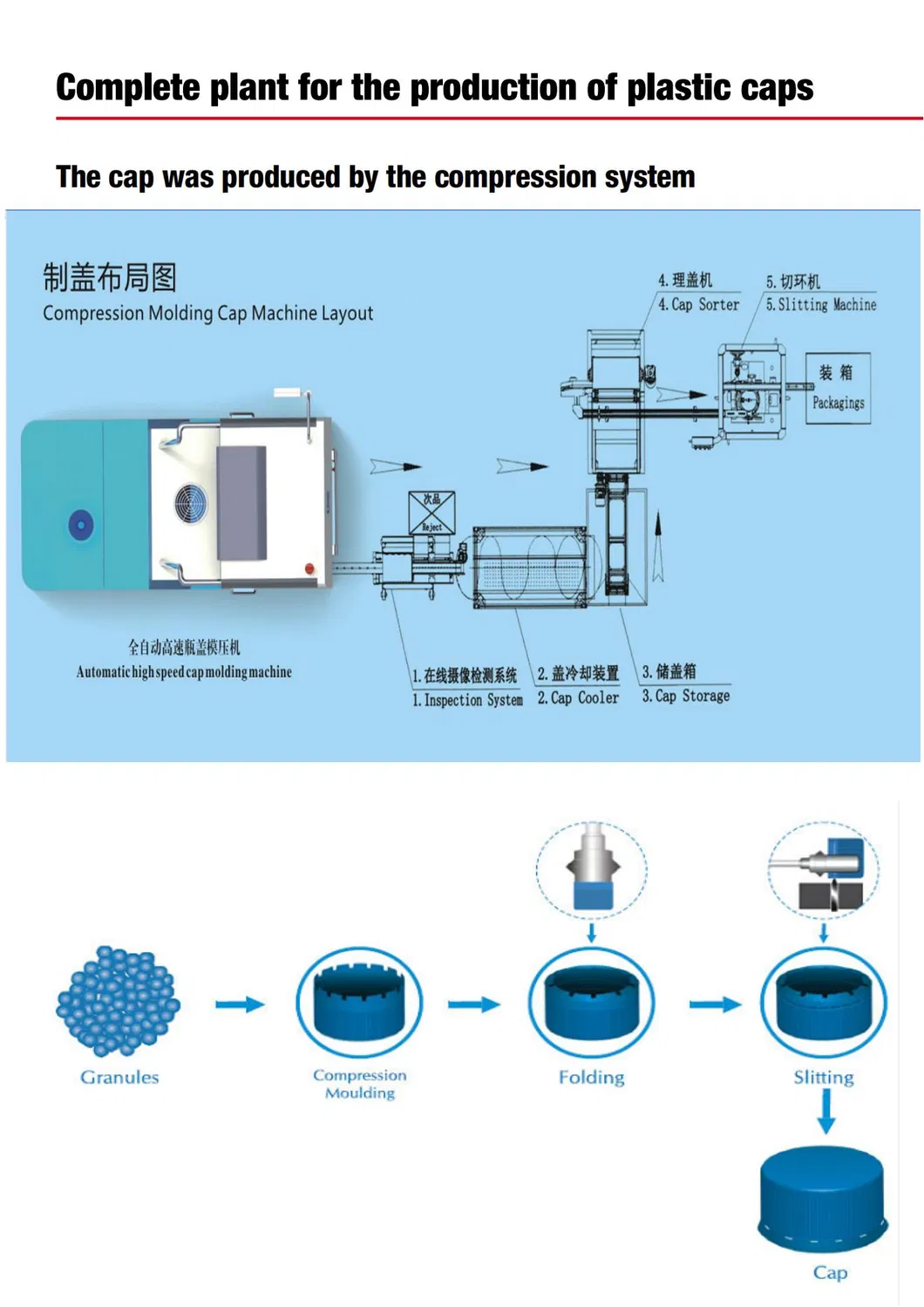

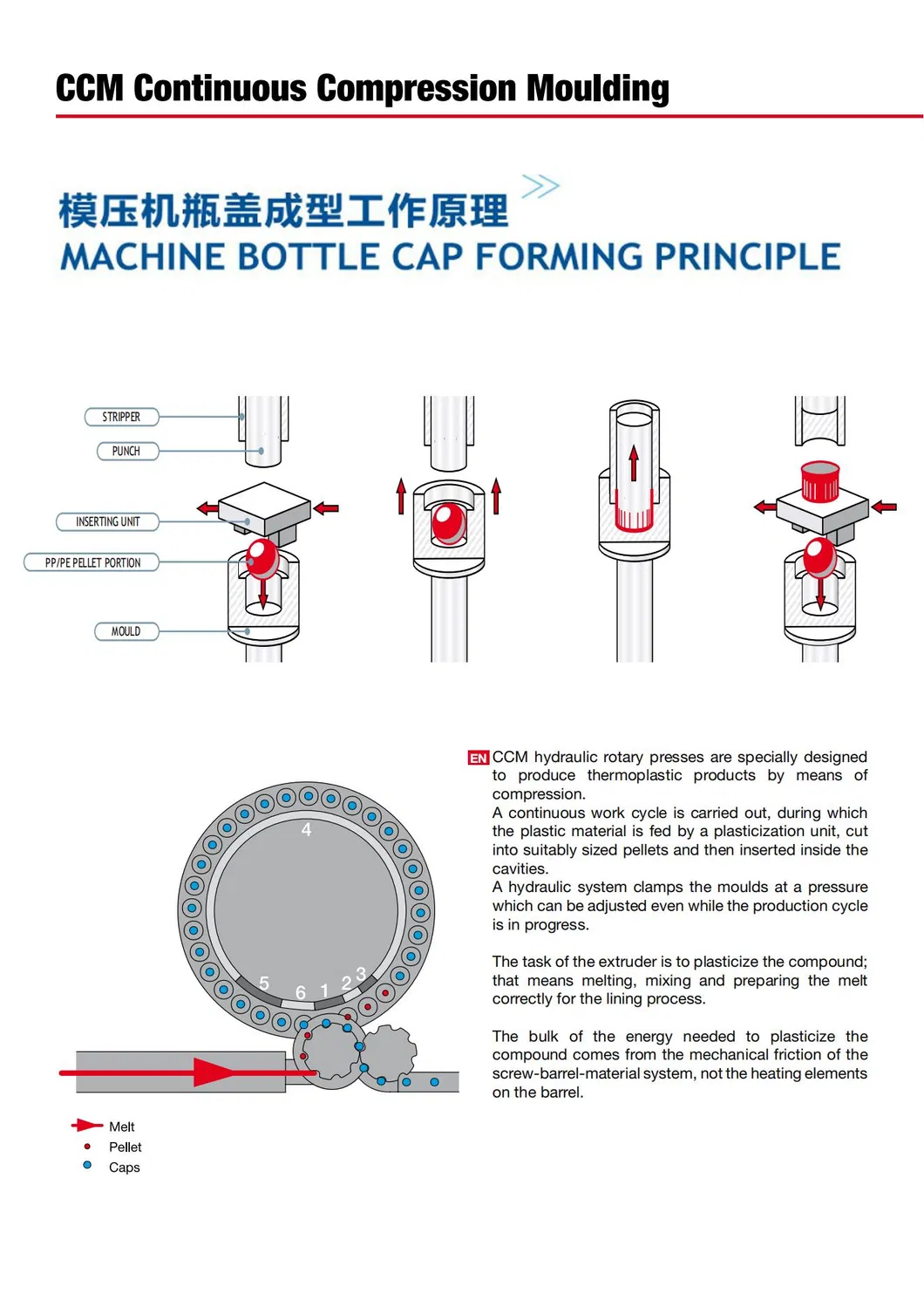

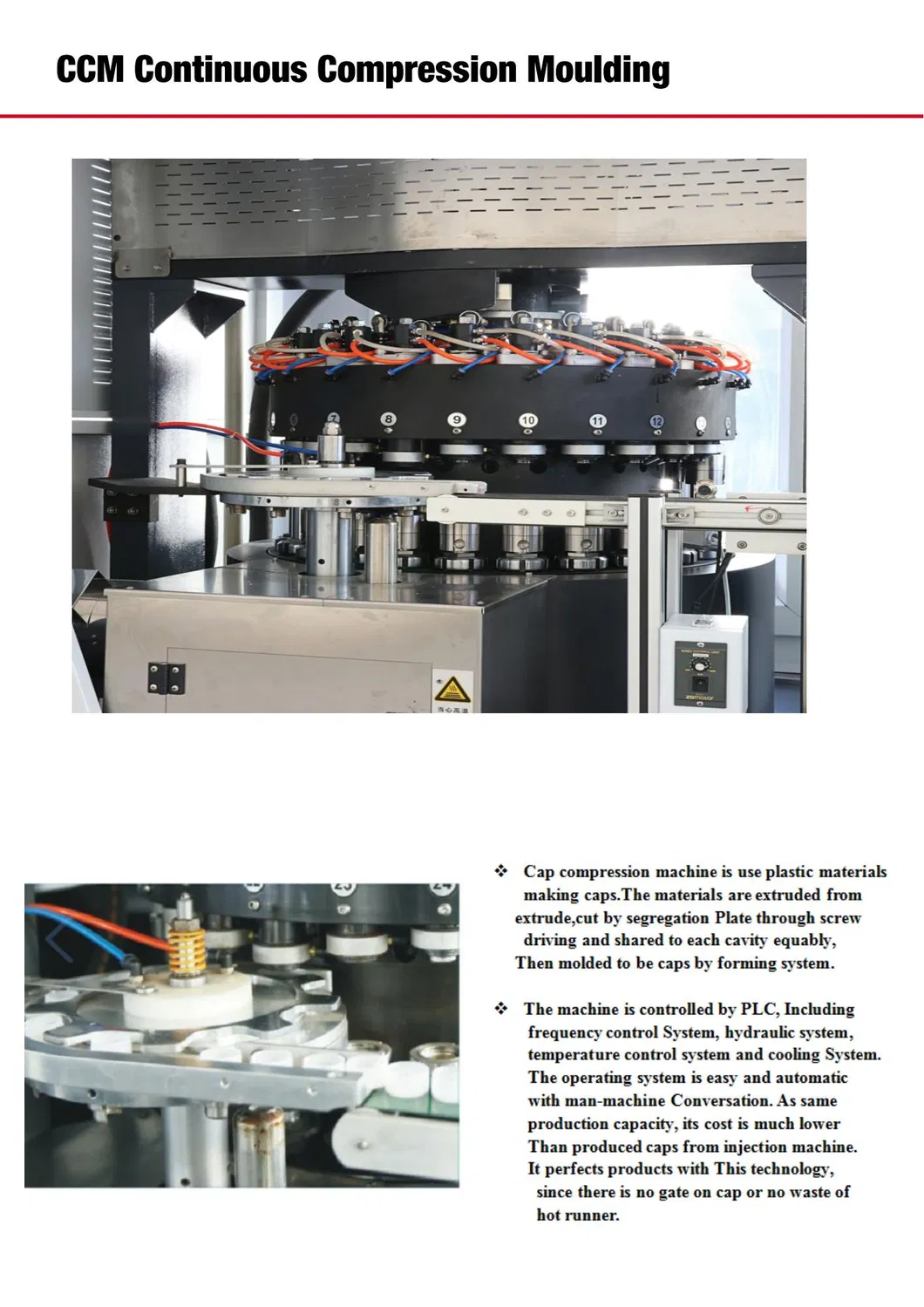

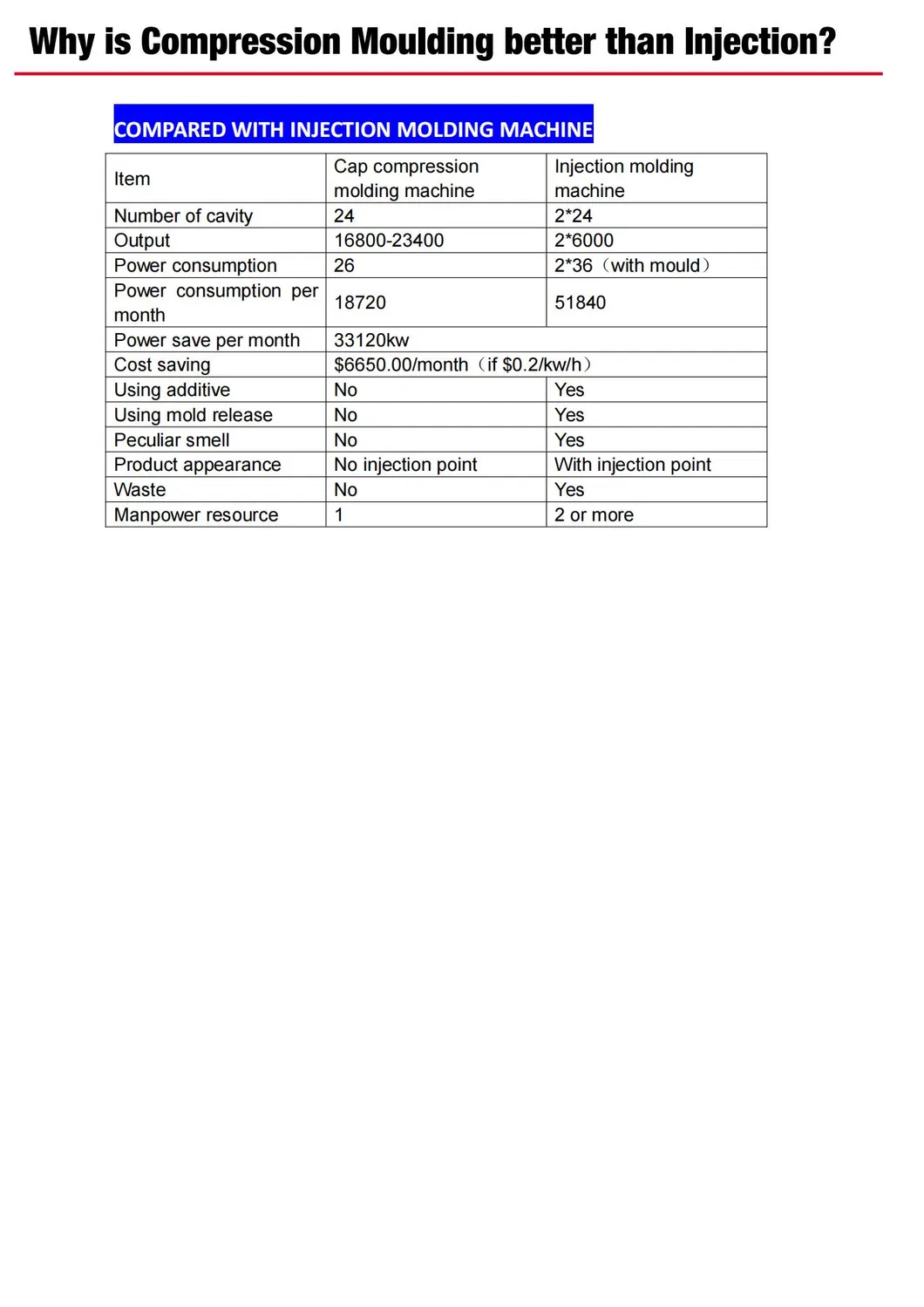

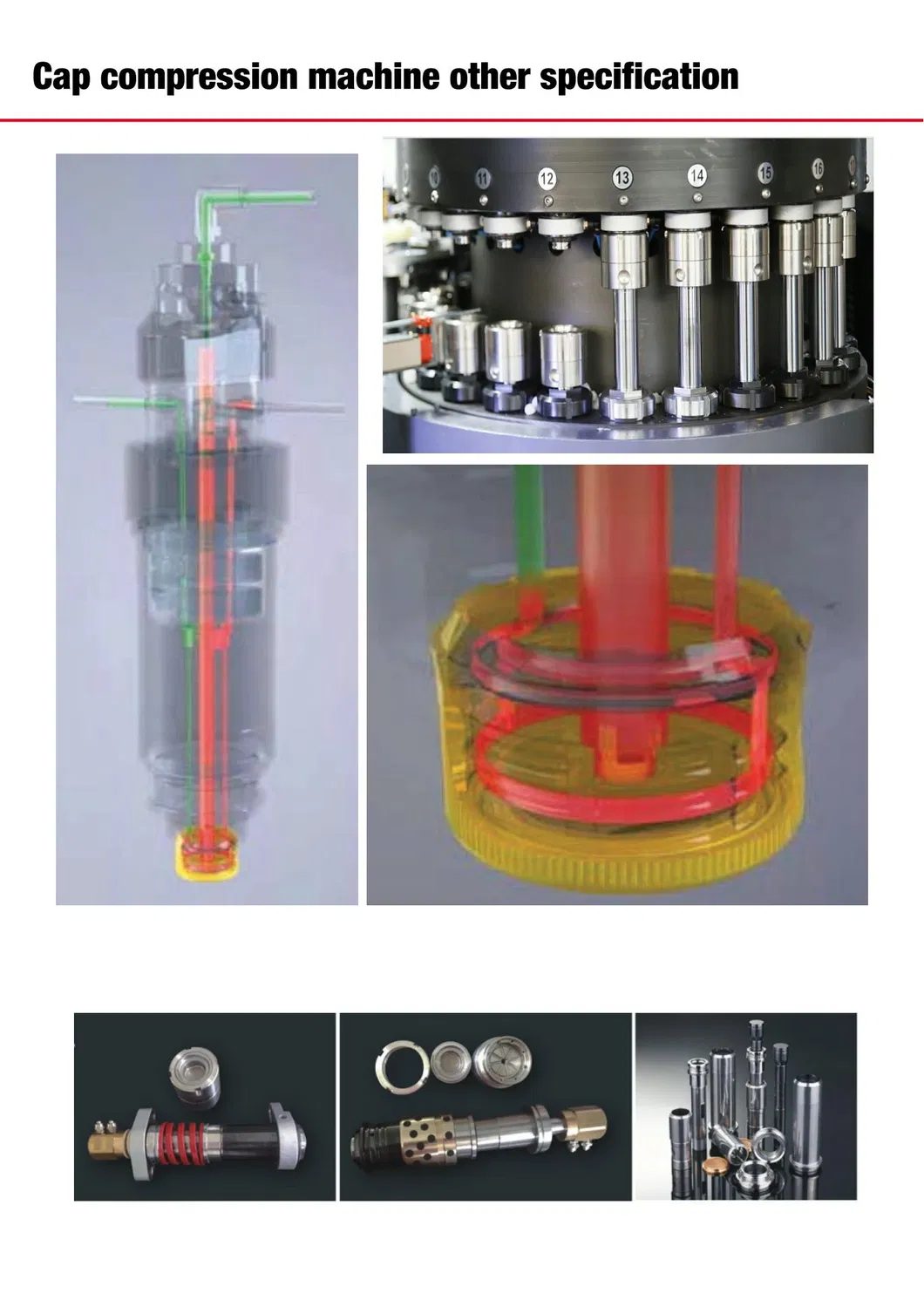

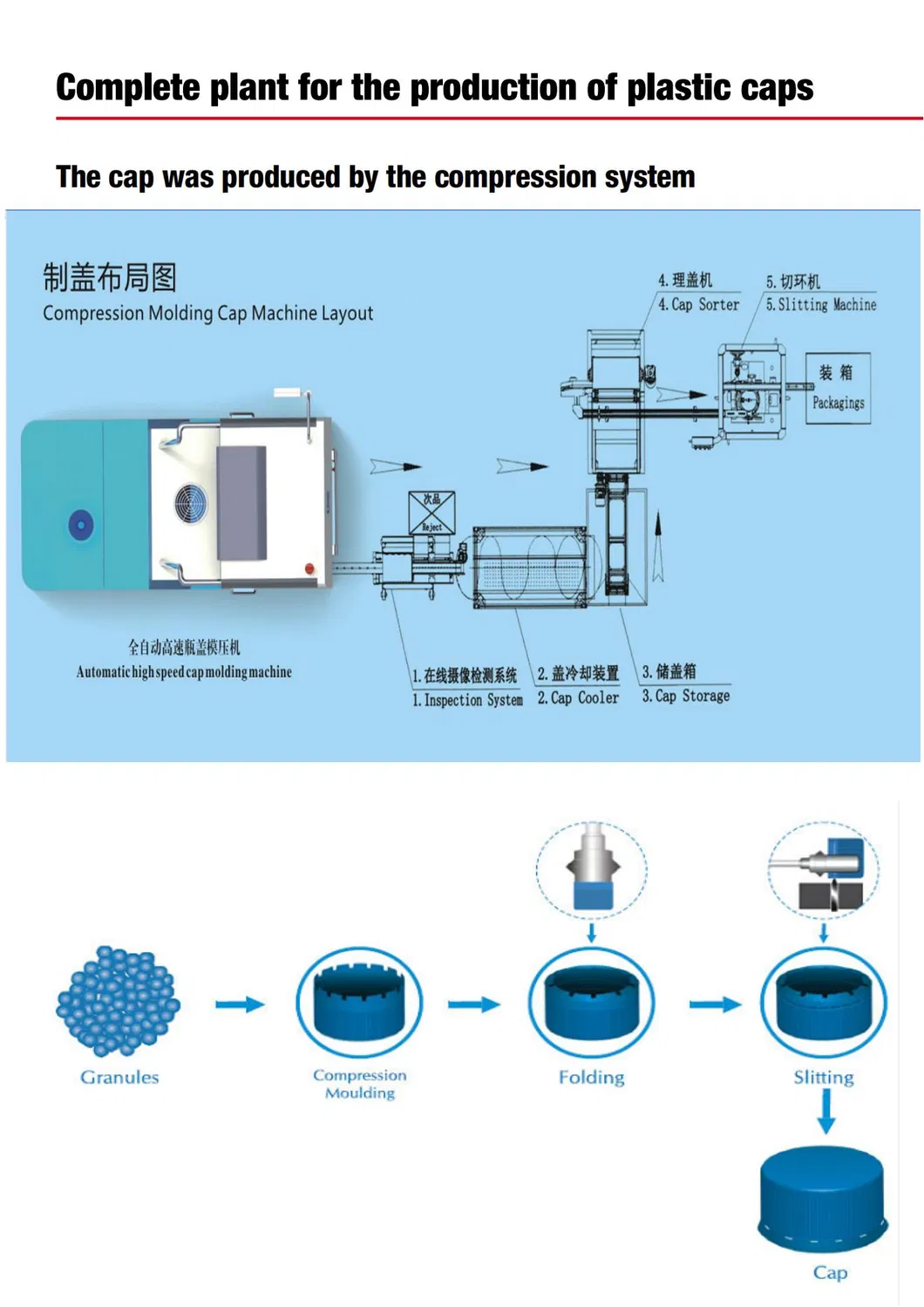

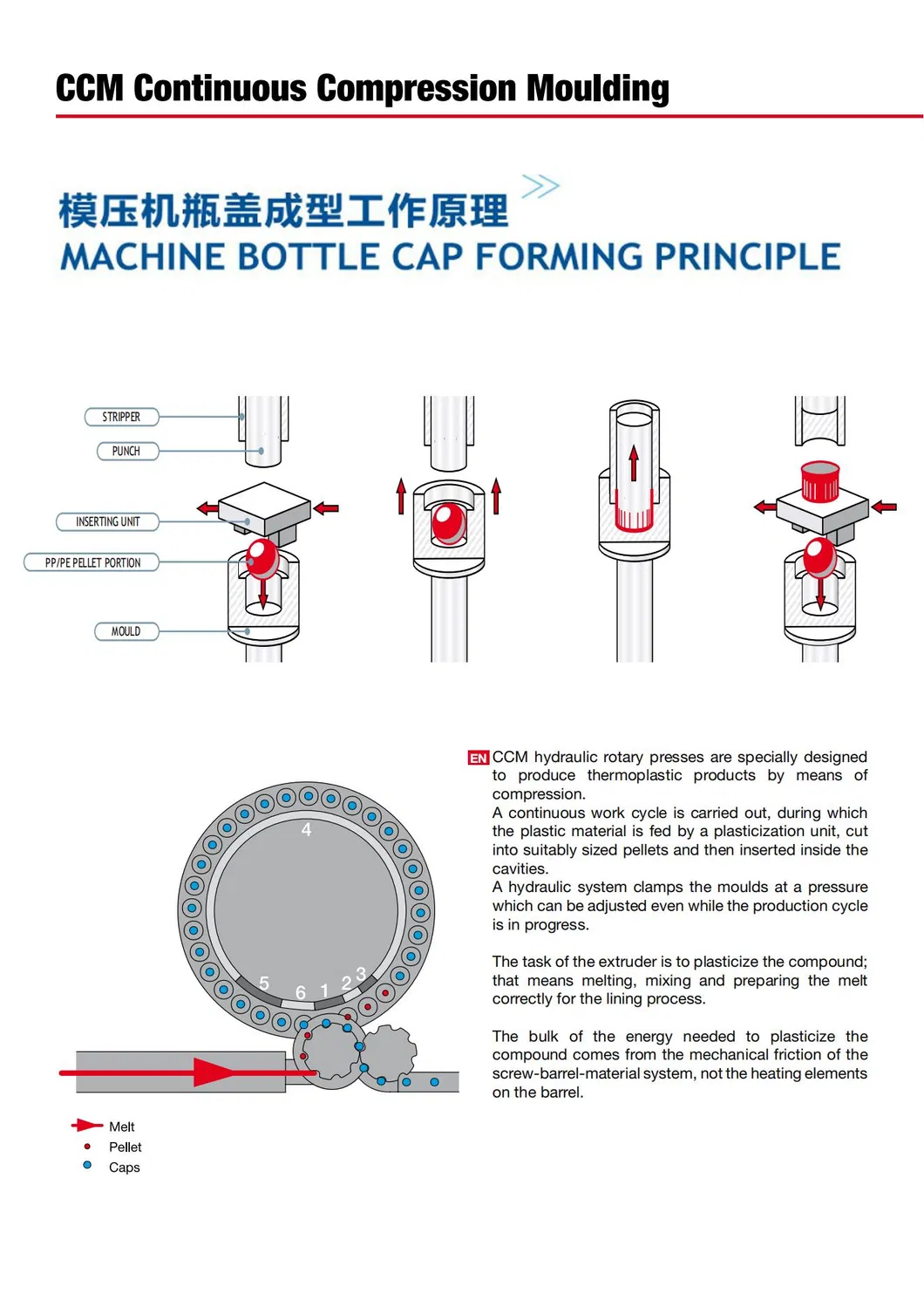

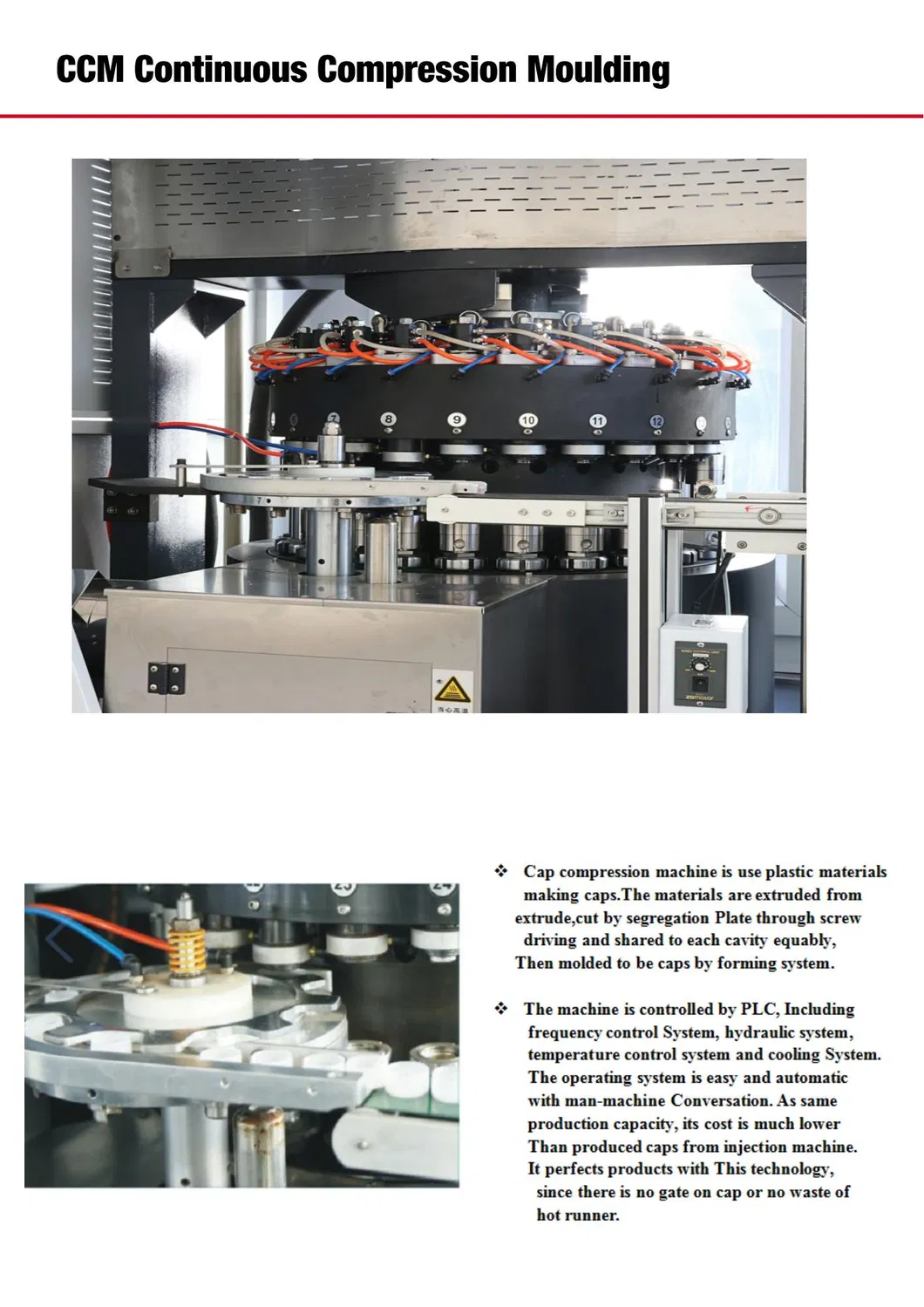

The cap Compression machine is already a well known used to produce plastic beverage caps, mineral water cap . Cap compression machine is use plastic materials making caps.The materials are extruded from extrude,cut by segregation Plate through screw driving and shared to each cavity equably,Then molded to be caps by forming system.The cap compression machine is controlled by PLC, Including frequency control System, hydraulic system,temperature control system and cooling System. The operating system is easy and automatic with man-machine Conversation. As same production capacity, its cost is much lower Than produced caps from injection machine.It perfects products with This technology, since there is no gate on cap or no waste of hot runner. It has no doubts as to the advantages offered by compression machine in terms of lower production costs and better product quality.

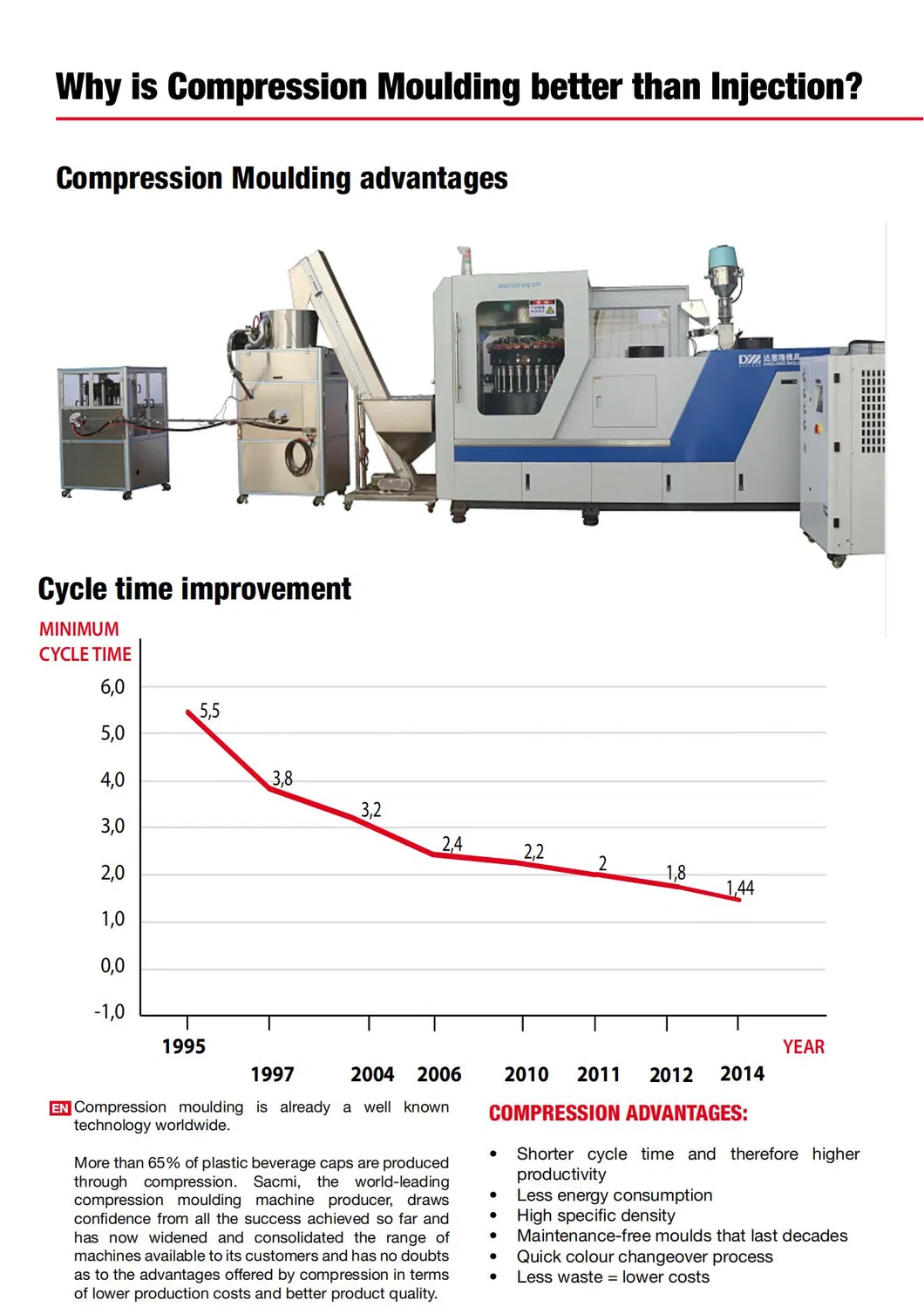

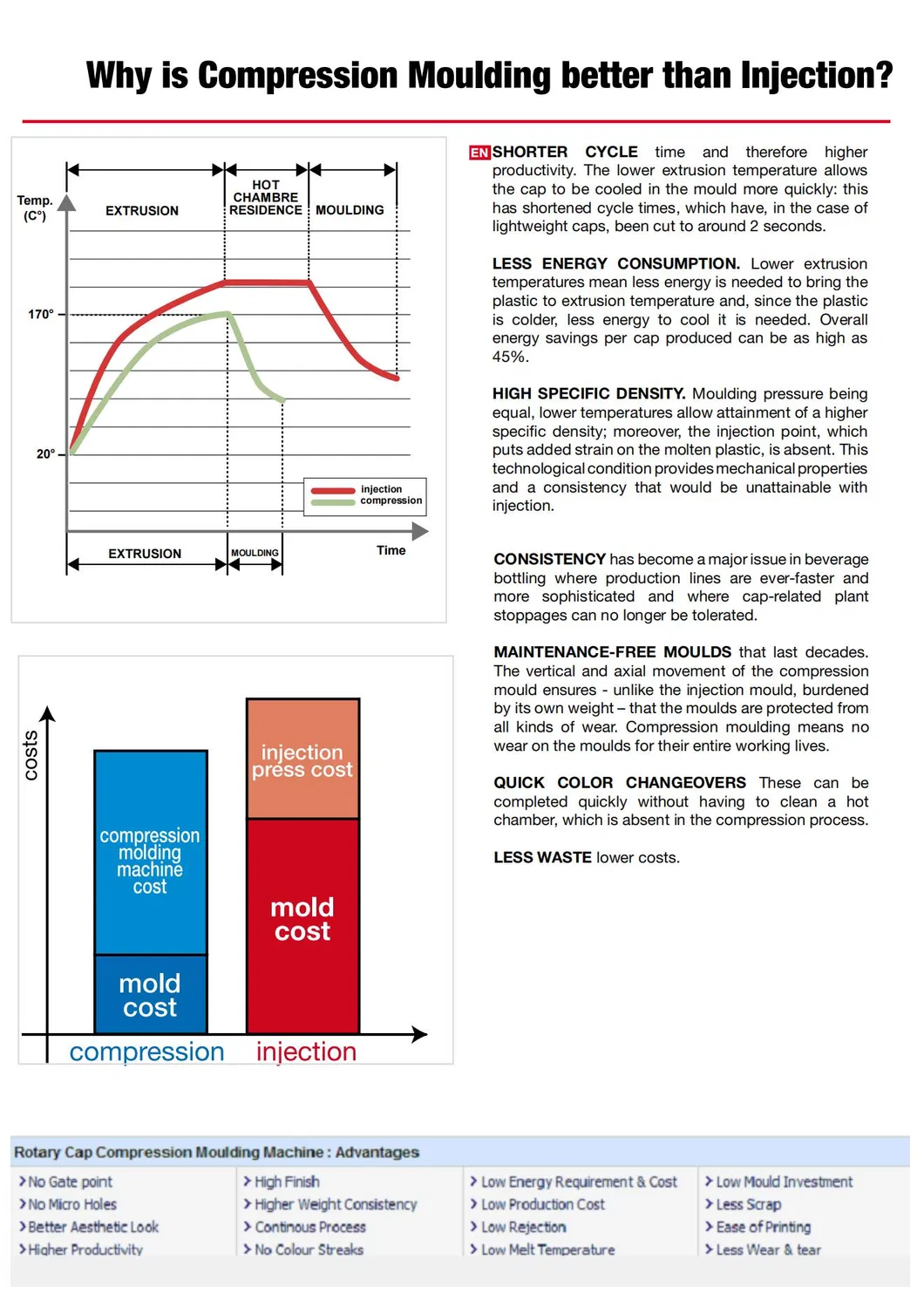

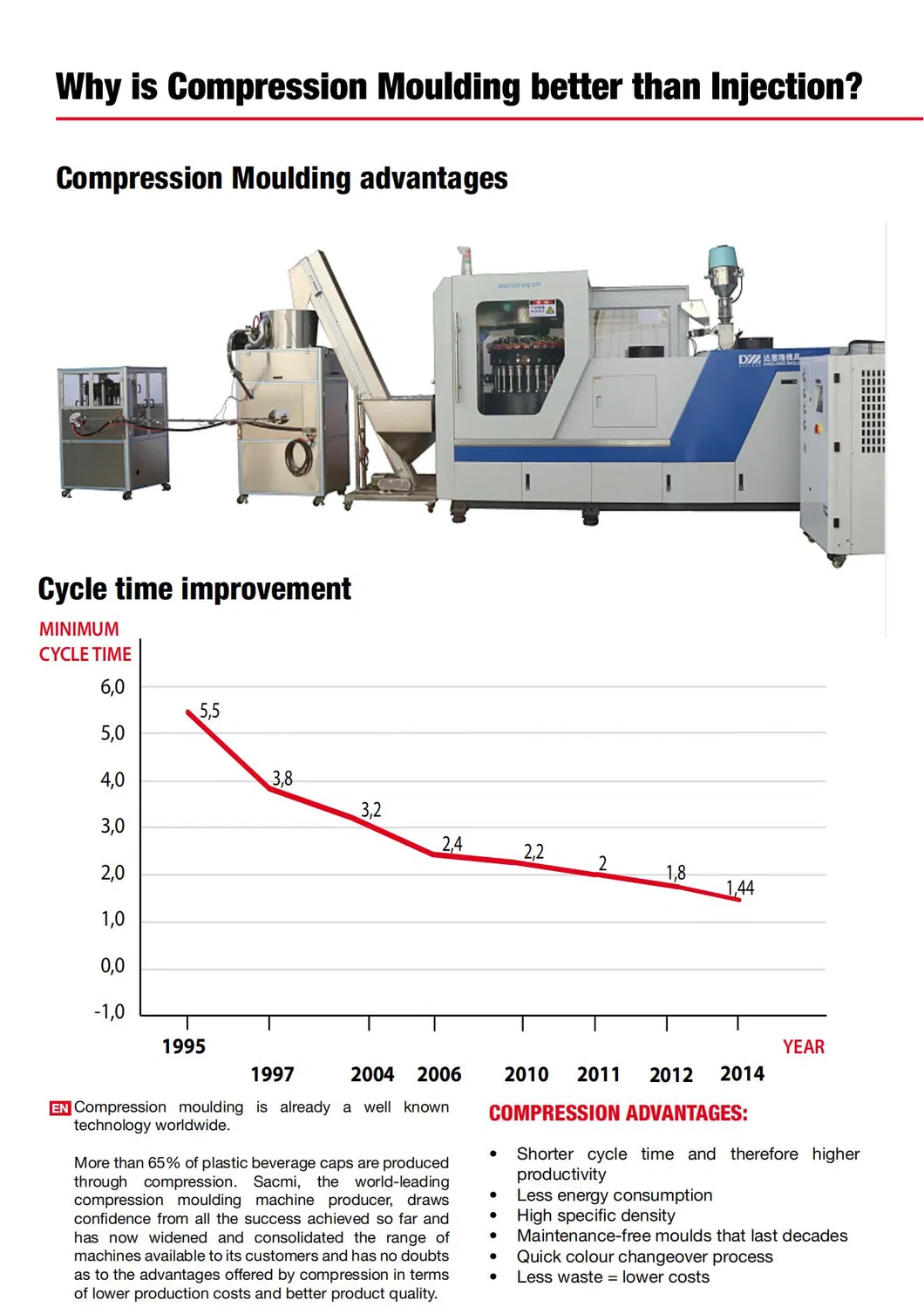

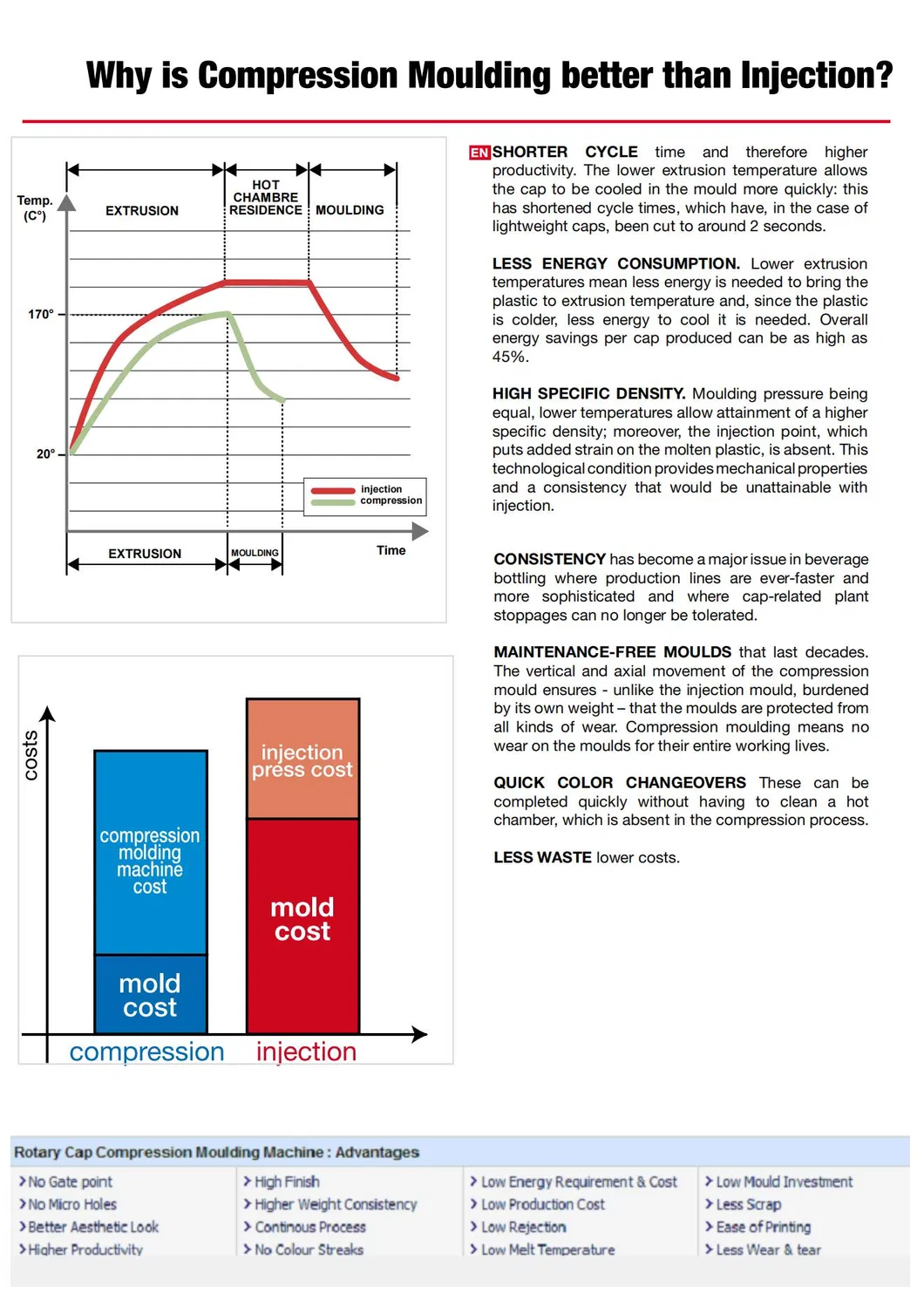

The Cap COMPRESSION MACHINE ADVANTAGES:

• Shorter cycle time for higher productivity

• Less energy consumption

• High specific density

• Maintenance-free molds that last decades

• Quick colour changeover process

• Less waste means lower costs

| General |

DRCM-032H |

| Description |

Unit |

Data details |

| Production Capacity |

30/25 mm cap |

Pcs./Hr. |

52000-55000 |

| PCO 1881 cap |

32000-35000 |

| Cap Diameter |

mm |

20-45 |

| Cap Height |

mm |

10-30 |

| Cap Material |

|

PP/PE |

| Electrical Requirement |

| Motor for Rotor |

kW |

95KW |

| Motor for Hydraulic Pump |

kW |

| Extruder Motor |

kW |

| Heater |

kW |

| Metering Pump |

kW |

autoloade of the cap

compression machine |

kW |

1 |

chiller of the cap

compression machine |

kW |

22Kw |

| Air conumption |

|

2.4M3/Hr,1.1Mpa |

| Voltage / Frequency |

Volts/Hz |

440/50 |

| 380/50 |

| |

Customization |

| Water Chiller |

Tr. |

20HP |

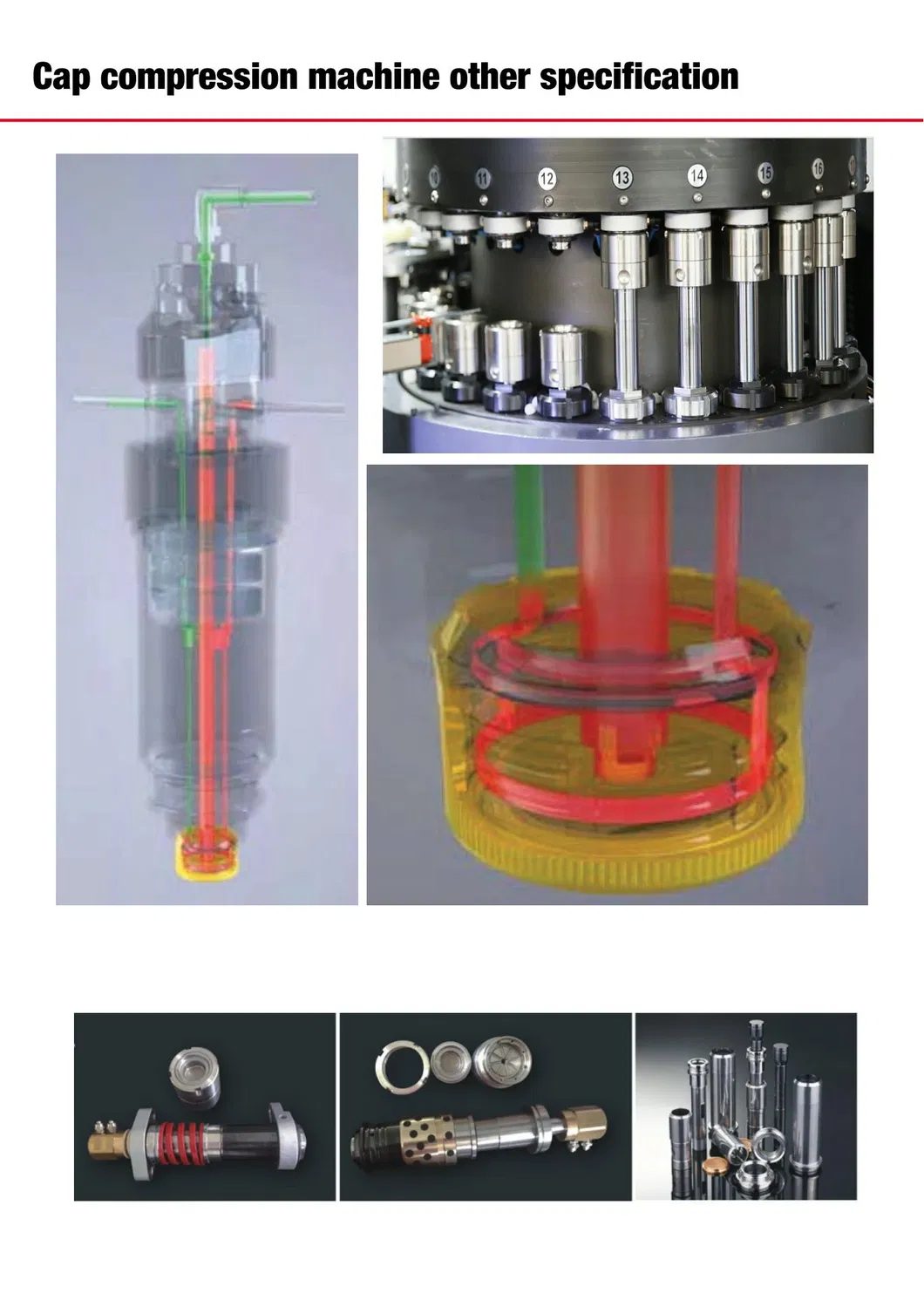

The specification of the cap compression mold

| Mould Material |

Cavity |

DC53, Japan |

| Cavity Base |

Beryllium Copper,USA |

| Cavity Pedestal |

S136 .Sweden |

| Screw of Cavity Pedestal |

DC53, Japan |

| Core |

Beryllium Copper,USA |

| Thread Part |

DC53, Japan |

| Medium Sleeve |

DC53, Japan |

| De-moulding Sleeve |

S136 .Sweden |

| Mould Hardness |

After vacuum igniting, -180°C cryogenic treatment, nitriding, then DLC(Diamond-Like Carbon), the mould hardness is around 70 degree. |

MOULD MANUFACTURE PROCESS

Cap mould: grinding--fly cutter--CNC Milling --Drilling --Lathe --Boring lathe --electric pulse --Finishing CNC -- EDM --Polishing --Installing -- Testing3.Interchangeable parts for every cavity.

BUSINESS STEPS

1. R&D We support customers R&D. We will make the files or improve the design if you need

2. Quotation Making mould quotation will be finished in 1 or 2 days according to the drawing & sample which you supplied.

3. Negotiation The negotiation includes quality, price, material,delivery time,payment term,ect.

4. Mould Design We need to spend 3-5 days on mould and product 3D/2D drawing design.

5. Mould We will build the mould based on customers's requirements. Before making the mold, we will send mold design to the customers for approval firstly.

6. Mould Testing When mold is finish, we will test the mold to check if the product will be satisfied with customer's requirements, and we will send samples to the customers for approval.

7. Delivery We will delivery the goods to the customers either by sea or by air.

FAQ

FAQ

Q: 1 Are you trading company or manufacturer ?

A: We are factory.

Q: 2 Where is your factory located?

A: Our factory is located in Huangyan, Taizhou city, Zhejiang Province, China.One hour from Taizhou airport by car, 15 minutes from train station to our factory.

Q: 3. How to go to your factory?

A: You can come to our city by flight, bus or train.

It takes 2 hours by flight from Guangzhou to our city.

It takes 3.5 hours by train from Shanghai to our city.

It takes 1 hour by bullet train from Ningbo to our city.

Q: 4.How about quality control in your factory?

A: We believe "Quality is above everything". We have professional team to control the quality. Our QC team mainly do the following procedures:

A) Design Optimize control

B) Mould steel hardness Inspection

C) Mould assembly Inspection

D) Mould trial report and samples Inspection

E) Final inspection for mould & packing before shipmentIf you have another question, pls feel free to contact us as below:

Q:5. If i provide you 3d drawing of my product, can you quote the price & make the mould as per the 3d drawing?

A:Yes.

DWG, DXF, STEP, IGS and X_T files can all be used to quote price, make mould as per your models - This can save time and money in producing your parts.

Q: 6. What type of plastic material is best for my design/component?

A: Plastic Materials selection depends on the application of your product. We will give you some suggestion after we checked the function of your component. And we can make the mould trial with different material according to your requirement.

Q: 7. What kind of mould can you make?

A: We can make all kinds of plastic injection moulds and blow moulds.

We can suggest you the proper cavity number as per your injection machines sizes.

Q:8. What's your payment method?

A: By T/T, L/C, Trade Assurance, Western Union.

FAQ

FAQ